Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

A Comprehensive Comparison of Handheld Alloy Analyzers: What You Need to Know

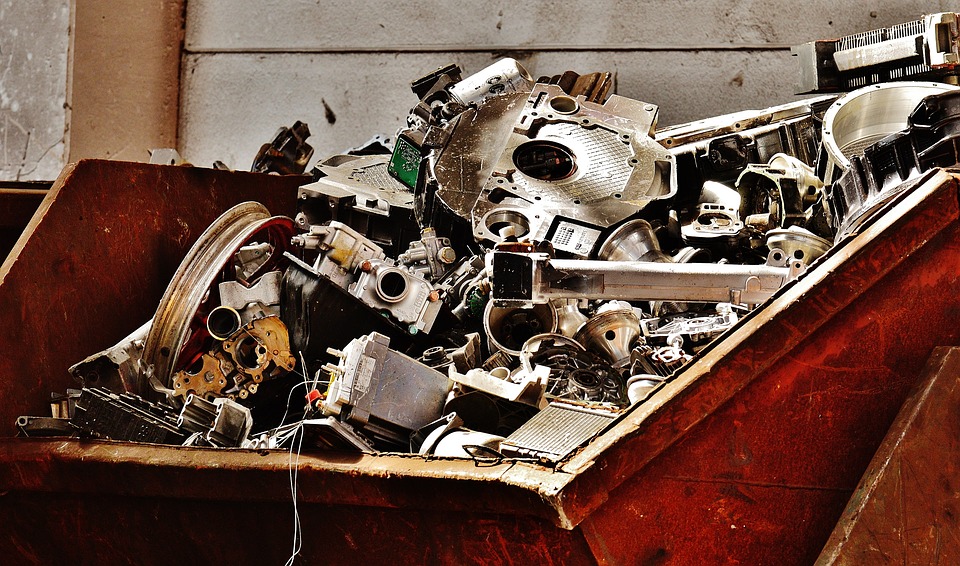

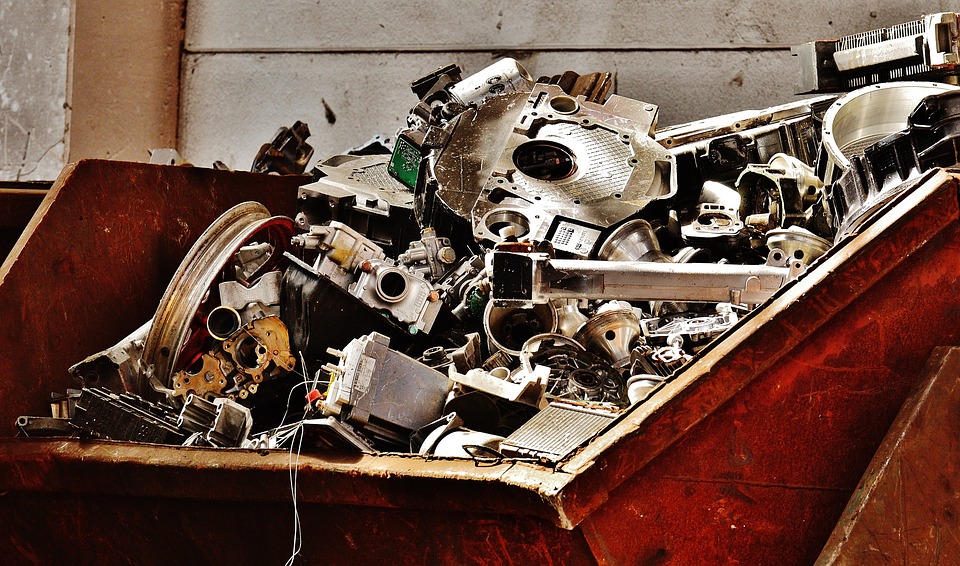

In today’s fast-paced world, industries from manufacturing to scrap recycling and quality control require rapid, accurate, and non-destructive analysis of metal alloys. Handheld alloy analyzers, also known as handheld spectrometers or metal analyzers, have revolutionized how professionals assess the composition of materials on-site. These portable devices have become indispensable tools for metalworking, construction, automotive, aerospace, and many other sectors. But with so many options available in the market, it can be challenging to choose the right handheld alloy analyzer for your needs.

In this comprehensive guide, we’ll compare various handheld alloy analyzers, focusing on their features, technology, and suitability for different applications. Whether you’re in the field of scrap metal recycling, quality control, or any other industry requiring precise material analysis, this article will help you make an informed decision.

Terras EulerX900 Handheld Alloy Analyzer

1. What Are Handheld Alloy Analyzers?

Handheld alloy analyzers are portable devices designed to quickly identify the elemental composition of metals and alloys. They use technologies like X-ray fluorescence (XRF), optical emission spectrometry (OES), or laser-induced breakdown spectroscopy (LIBS) to analyze metal samples. These tools offer the advantage of rapid results and ease of use, making them perfect for on-site analysis where laboratory testing isn’t feasible.

Key Uses:

Scrap metal sorting: Quickly determine the type of metal for recycling or resale.

Quality control: Verify the alloy content of materials during manufacturing or inspection processes.

Field testing: Test metals in construction or manufacturing sites without needing a lab.

Regulatory compliance: Ensure the material meets the required standards and certifications.

2. Technologies Used in Handheld Alloy Analyzers

The technology behind alloy analyzers determines the speed, accuracy, and depth of analysis. Below are the main technologies used:

X-Ray Fluorescence (XRF)

XRF is one of the most common methods for handheld alloy analyzers. It works by bombarding the material with X-rays, causing the atoms in the sample to emit fluorescent X-rays. The device then measures these emissions to determine the elemental composition of the metal.

Pros:

Non-destructive

Fast results (usually in seconds)

Low maintenance

Can analyze a wide range of elements

1. Accuracy and Precision

Different technologies offer varying degrees of accuracy. For general sorting tasks, XRF might be sufficient, but if you need precise, high-confidence results, OES would be more appropriate. Consider the type of alloys you work with and the degree of precision you need.

2.Range of Elements

XRF analyzers excel at detecting a broad range of elements, but they are less sensitive to lighter elements (e.g., lithium, beryllium). If your work involves these elements, an OES analyzer may be better suited for your needs.

3. Durability and Portability

For professionals working in harsh environments (e.g., construction sites or scrap yards), durability is critical. Choose an analyzer that is rugged, dust- and water-resistant, and built to withstand physical wear. Check for IP ratings (e.g., IP67, IP65) that ensure the device is resistant to dust and water.

4. Battery Life

Look for handheld analyzers with long battery life, especially if you need to perform multiple tests on the go. Some analyzers offer continuous operation for 8–12 hours on a single charge, which is ideal for fieldwork.

5. User-Friendliness

Consider devices that are easy to operate and provide clear results. Some analyzers come with intuitive touchscreens, pre-programmed alloys, and detailed reporting capabilities that can save time during analysis and interpretation.

6. Cost

Cost is a significant consideration, as handheld analyzers can range from a few thousand to tens of thousands of dollars. XRF devices tend to be more affordable, while OES and LIBS devices are typically pricier but offer enhanced precision and capabilities. Assess your budget and evaluate the long-term ROI based on your specific needs.

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. This makes it an ideal tool for inspecting and analyzing incoming materials, finished products, and in-process production parts in a non-destructive manner. Its simplicity of operation allows users to quickly view alloy grade and chemical composition on the touch screen display, achieving laboratory-quality analysis with minimal training and virtually no need for sample preparation, regardless of the sample is shape or size.

Terras EulerX900 Handheld Alloy Analyzer

5. Conclusion

Choosing the right handheld alloy analyzer depends on your specific needs—whether you require quick, on-the-spot analysis for metal sorting, or highly accurate testing for complex alloy compositions. If you need a more general-purpose device for quick and relatively accurate results, an XRF analyzer like the Thermo Scientific Niton XL3t or Olympus Vanta is a solid choice. However, for high-precision applications, such as in aerospace or automotive industries, OES devices like the Spectro Xepos will offer better accuracy and deeper insights into the elemental composition.

Regardless of your choice, handheld alloy analyzers are a valuable investment for industries that demand efficiency, accuracy, and versatility in material testing. By considering the technology, durability, accuracy, and specific use case requirements, you can find the right device that will help streamline operations, enhance quality control, and drive efficiency in your workflow.

Join Us

Subscribe to our email list for updates & promotions.