XRF Technology

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Common Challenges and Solutions When Using Handheld XRF Analyzer Guns

Handheld XRF (X-ray fluorescence) analyzer guns are powerful tools for materials analysis, offering quick and non-destructive testing across various industries. However, users often encounter challenges that can affect accuracy and efficiency. Here’s a look at some common issues and their solutions.

1. Calibration Issues

Challenge: Proper calibration is crucial for accurate results. Handheld XRF analyzers can drift from calibration, leading to erroneous readings.

Solution: Regularly calibrate the device using certified standards. Follow the manufacturer’s guidelines for calibration intervals and procedures to maintain accuracy.

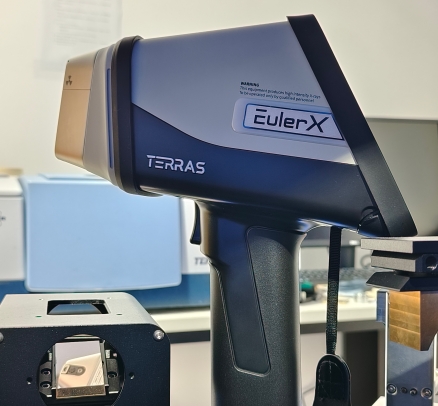

Terras EulerX900 Handheld Alloy Analyzer

2. Sample Contamination

Challenge: Contaminants on the sample surface can interfere with the analysis, leading to skewed results.

Solution: Ensure samples are clean and free from dust, oils, or other contaminants. Use appropriate cleaning methods and inspect samples before testing.

3. Interference from Other Elements

Challenge: The presence of certain elements can cause spectral interference, complicating the analysis of target elements.

Solution: Utilize the device’s built-in software to identify and correct for potential interferences. Additionally, conduct multiple tests to confirm results and reduce error margins.

4. Inconsistent Results

Challenge: Variability in results can occur due to inconsistent sample positioning or varying material properties.

Solution: Standardize sample positioning and use a consistent technique for analysis. Ensure proper contact between the analyzer and the sample to minimize variability.

5. Environmental Factors

Challenge: Environmental conditions like temperature and humidity can affect the performance of handheld XRF analyzers.

Solution: Operate the device within the recommended environmental range provided by the manufacturer. If working in extreme conditions, use protective measures or specialized equipment.

6. Device Handling and Training

Challenge: Inadequate training or improper handling can lead to user error and inaccurate results.

Solution: Provide comprehensive training for users on the proper operation of the device. Regularly review handling procedures and encourage adherence to best practices.

Terras EulerX900 Handheld Alloy Analyzer

7. Data Interpretation

Challenge: Interpreting XRF data requires a solid understanding of the analytical results and their implications.

Solution: Use the software tools provided with the device for data analysis and interpretation. Consult with experts or seek training to enhance your ability to interpret complex data accurately.

Addressing these challenges effectively can enhance the reliability and precision of handheld XRF analyzer guns, ultimately leading to better material analysis and decision-making.

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. The applications of the EulerX 900 handheld are extensive, covering not only solids but also liquids and powders. Designed for ergonomic comfort, the device is lightweight, compact, and well-balanced for handheld use. A high-capacity battery allows for 10-12 hours of continuous on-site testing without the need for recharging.

Join Us

Subscribe to our email list for updates & promotions.