Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

How to Calibrate and Optimize Your Hand Held Metal Analyser for Accurate Results

Handheld metal analyzers are indispensable tools for various industries, from manufacturing and recycling to geology and archaeology. To ensure you get the most accurate and reliable results, it’s crucial to properly calibrate and optimize your device. In this article, we’ll guide you through the essential steps to achieve precise readings from your handheld metal analyzer.

Terras EulerX900 Handheld Alloy Analyzer

1. Understand Your Analyzer

Before diving into calibration, familiarize yourself with your metal analyzer’s specifications and operational guidelines. Different models might have varying calibration procedures, so it’s important to refer to the user manual provided by the manufacturer. Common types of handheld metal analyzers include X-ray fluorescence (XRF) analyzers and optical emission spectrometers (OES), each with its calibration requirements.

2. Preparation for Calibration

A. Gather Calibration Standards

Obtain high-quality calibration standards that are certified and traceable to national or international standards. These standards should closely match the materials you intend to analyze to ensure accuracy.

B. Clean the Analyzer

Before starting calibration, clean the probe and any contact surfaces to remove dust, dirt, or residue. Contaminants can affect calibration accuracy and interfere with measurements.

C. Warm Up the Analyzer

Allow your analyzer to warm up as recommended by the manufacturer. Most handheld analyzers require a warm-up period to stabilize internal components and achieve optimal performance.

3. Performing the Calibration

A. Select the Calibration Mode

Access the calibration mode on your device. This is usually found in the settings or setup menu. Follow the instructions provided in the user manual for the specific calibration procedure of your model.

B. Calibrate Using Standards

Follow the manufacturer’s procedure for calibrating the analyzer with your standards. Typically, this involves:

Placing the calibration standard in the measurement area.

Running the calibration routine as directed by the device’s software.

Allowing the device to process the standard and adjust its internal settings.

C. Validate Calibration

After calibration, use additional known standards to validate the accuracy of the calibration. This step ensures that the analyzer provides correct readings across a range of materials.

4. Optimize Performance

A. Regular Maintenance

Regular maintenance of your handheld metal analyzer is essential for consistent performance. Follow the maintenance schedule provided by the manufacturer, which may include cleaning, battery replacement, and software updates.

B. Update Software

Keep the analyzer’s software up-to-date to benefit from the latest improvements and bug fixes. Check the manufacturer’s website or contact customer support for software updates.

C. Monitor Environmental Conditions

Environmental factors such as temperature, humidity, and electromagnetic interference can impact your analyzer’s performance. Try to operate the device in controlled conditions and minimize exposure to extreme environments.

D. Train Users

Ensure that all users are properly trained in the operation and calibration of the analyzer. Proper technique and understanding of the device’s functionality can significantly affect measurement accuracy.

5. Document and Record Results

Keep detailed records of all calibration procedures, including dates, standards used, and calibration results. This documentation is valuable for tracking the performance of your analyzer over time and for troubleshooting any issues that arise.

Terras EulerX900 Handheld Alloy Analyzer

6. Troubleshooting Calibration Issues

If you encounter discrepancies or inconsistencies in your measurements:

Verify that the calibration standards used are still valid and accurate.

Ensure that the analyzer has been properly cleaned and maintained.

Consult the user manual for troubleshooting tips or contact the manufacturer’s support team for assistance.

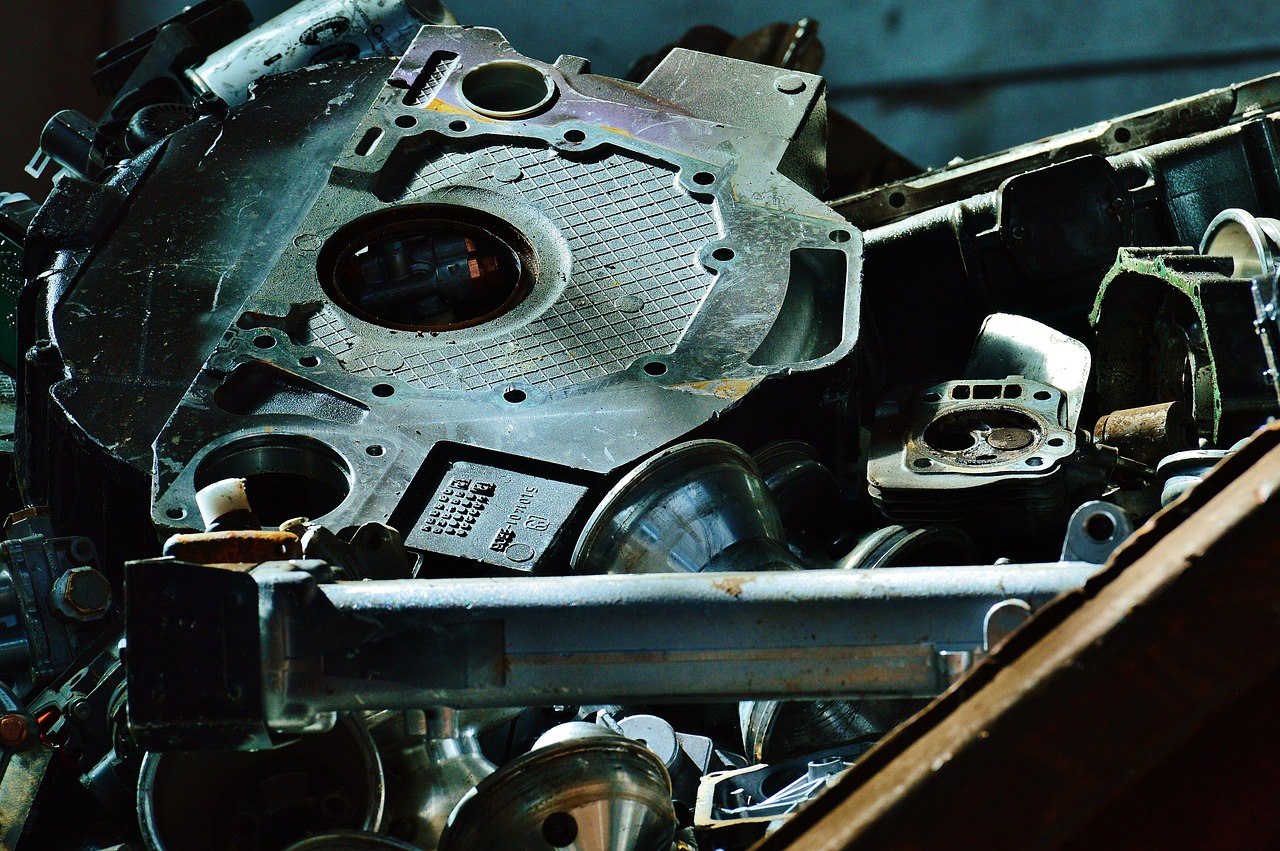

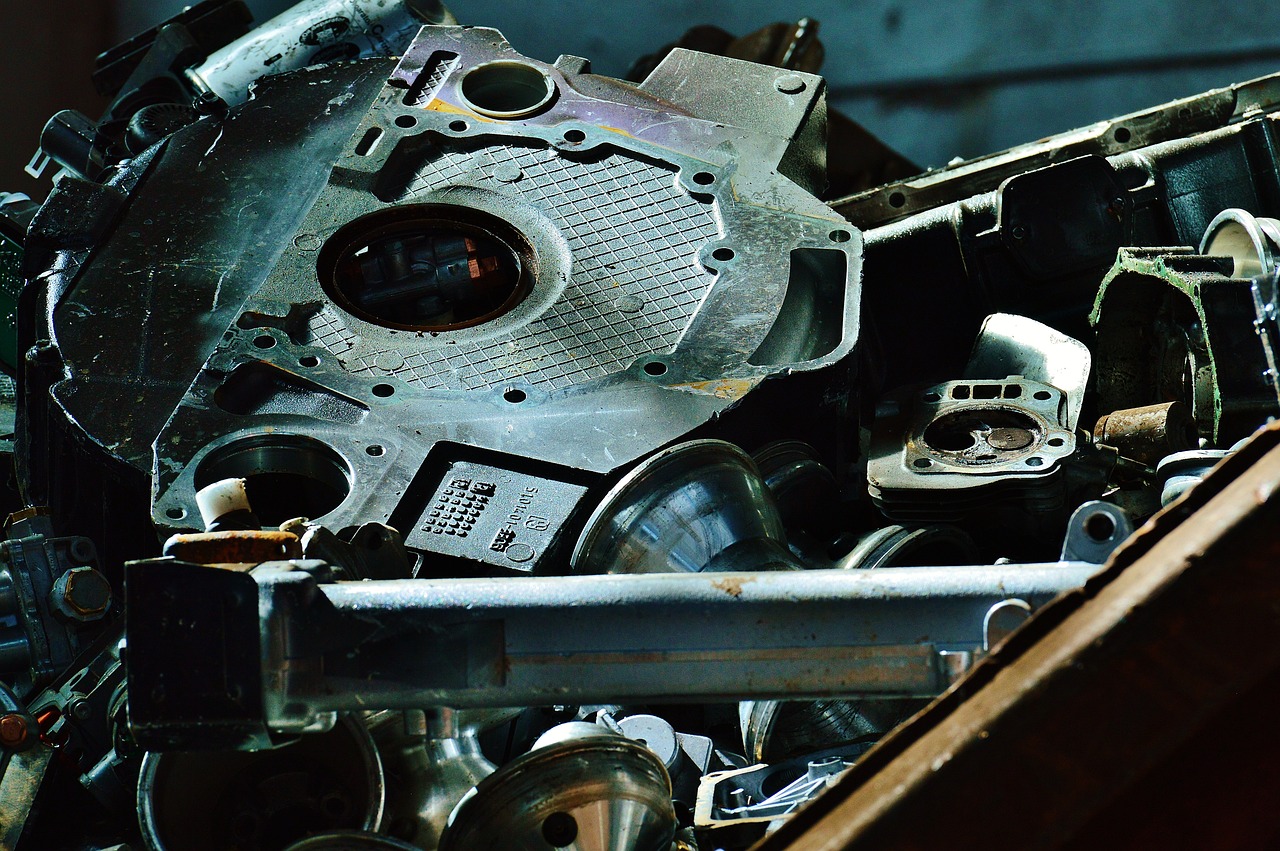

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. The applications of the EulerX 900 handheld are extensive, covering not only solids but also liquids and powders. The EulerX 900 series handheld alloy analyzers are extensively utilized for alloy grade identification and quality control, scrap metal recycling, precious metals analysis, PMI, and more.

Conclusion

Proper calibration and optimization of your handheld metal analyzer are crucial for obtaining accurate and reliable results. By following the steps outlined above, you can ensure that your device remains in peak condition and continues to provide precise measurements. Regular maintenance, training, and attention to detail will help you get the most out of your analyzer and achieve the best possible outcomes for your analysis needs.

For more tips and information on maintaining your handheld metal analyzer, stay tuned to our blog or reach out to our support team for personalized assistance.

Join Us

Subscribe to our email list for updates & promotions.