Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

The Role of Catalytic Converter Analysis in Reducing Environmental Pollution-XRF technology

In recent years, the environmental impact of vehicle emissions has been a growing concern. As governments and industries work to curb pollution and reduce the environmental footprint of transportation, catalytic converters have become a critical part of this global effort. Catalytic converters help reduce harmful emissions from internal combustion engines by transforming toxic gases into less harmful substances. But how do we ensure that these devices are functioning at their best? The answer lies in an advanced technique known as X-ray fluorescence (XRF) technology.

What is a Catalytic Converter?

A catalytic converter is a key component of a vehicle’s exhaust system. Its primary function is to reduce harmful pollutants—such as carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC)—into less harmful substances like carbon dioxide (CO2), nitrogen (N2), and water vapor (H2O). These converters contain precious metals like platinum (Pt), palladium (Pd), and rhodium (Rh), which act as catalysts in chemical reactions that break down harmful emissions.

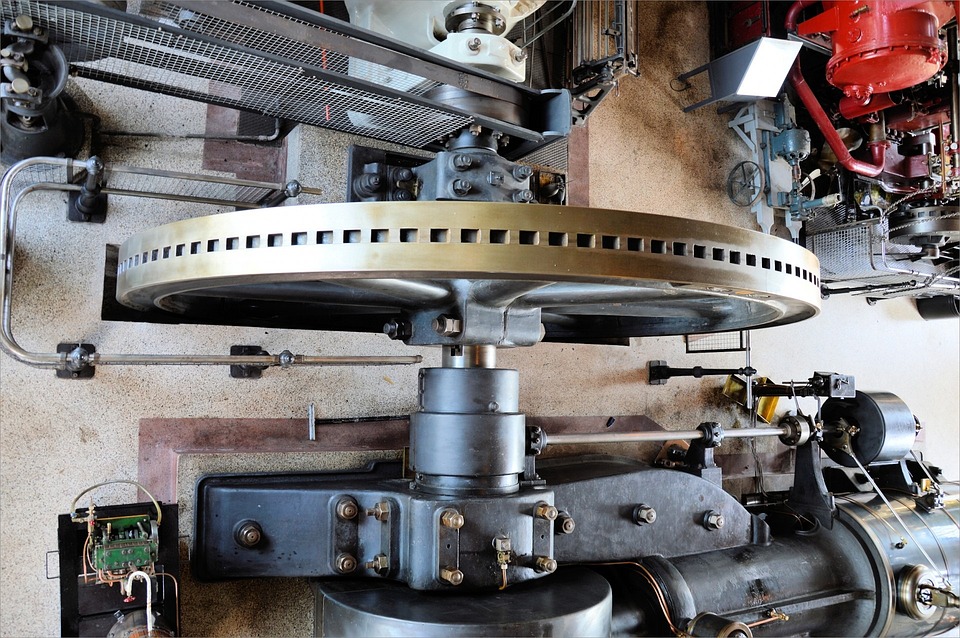

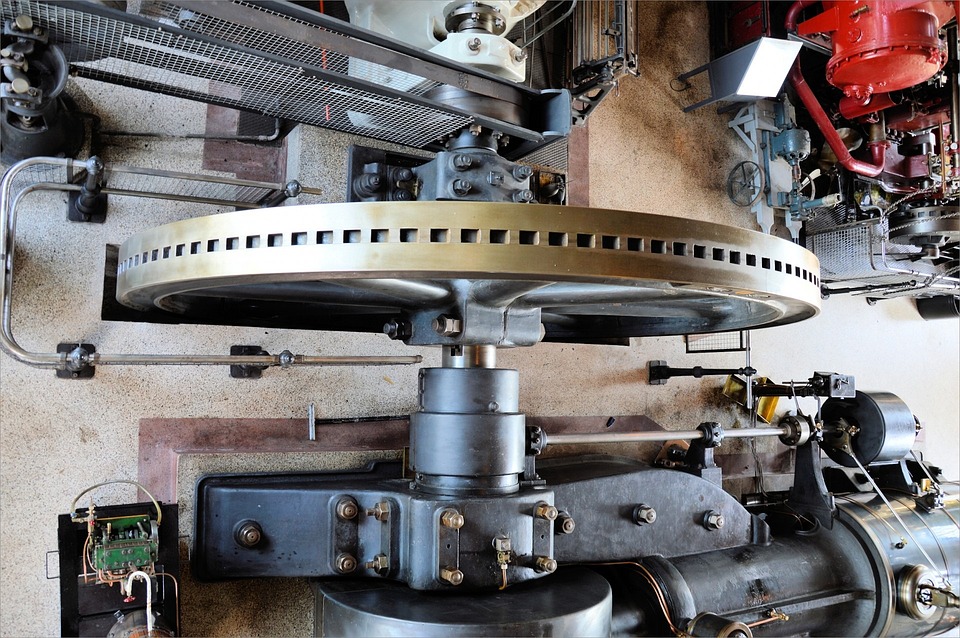

Terras EulerX900 Handheld Alloy Analyzer

Why Catalytic Converter Analysis Matters

The efficiency of a catalytic converter directly impacts a vehicle's emissions output. When the catalytic converter is damaged, inefficient, or failing, the vehicle can emit pollutants at levels that exceed regulatory limits. This can result in not only environmental harm but also legal consequences for manufacturers, fleet operators, and individual vehicle owners.

Analyzing catalytic converters allows for:

Early Detection of Degradation: Regular analysis helps identify when a catalytic converter is beginning to fail, preventing excessive emissions before they become problematic.

Optimization of Emission Control: Accurate analysis ensures that catalytic converters are working optimally, helping vehicles meet stringent emission standards set by governments.

Recycling and Recovery of Precious Metals: The valuable metals used in catalytic converters can be recovered through analysis and recycling processes, reducing the need for mining and further contributing to sustainability.

Compliance with Environmental Regulations: Many countries have strict emissions standards, and catalytic converter analysis is essential for ensuring that vehicles meet these standards.

The Role of XRF Technology in Catalytic Converter Analysis

X-ray fluorescence (XRF) is a non-destructive analytical technique used to determine the elemental composition of materials. In the context of catalytic converter analysis, XRF technology can quickly and accurately assess the content and condition of precious metals (such as platinum, palladium, and rhodium) in the catalyst material.

How XRF Works

XRF works by directing high-energy X-rays onto a sample (in this case, a catalytic converter), causing atoms in the sample to emit fluorescent X-rays. These fluorescent X-rays are then analyzed to identify the elements present and their concentrations. XRF provides instant results, making it an ideal tool for on-site testing, quality control, and compliance monitoring.

Benefits of XRF in Catalytic Converter Analysis

Non-Destructive Testing: XRF technology allows for the analysis of catalytic converters without damaging or altering the components. This is especially important in situations where the converter may be reused, recycled, or resold.

High Precision and Accuracy: XRF can identify the precise quantities of precious metals within the catalyst, providing valuable information about the converter’s condition and remaining lifespan. This helps vehicle manufacturers, service providers, and recyclers make informed decisions regarding replacement, repair, and recycling.

Fast and Convenient: Traditional methods of analyzing catalytic converters often require sample preparation and lengthy lab processes. XRF, on the other hand, delivers rapid results with minimal sample preparation. In the automotive industry, this translates to quicker diagnostics and better decision-making.

The use of XRF spectrometry has been a cornerstone in metal analysis for decades, valued for its efficiency and reliability. It serves as a crucial quality control instrument in numerous metal processing environments, prized for its portability, which allows for testing anywhere and anytime, and its user-friendly operation and maintenance.

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. This makes it an ideal tool for inspecting and analyzing incoming materials, finished products, and in-process production parts in a non-destructive manner.

Terras EulerX900 Handheld Alloy Analyzer

XRF Technology in the Recycling Industry

In addition to its use in automotive diagnostics, XRF plays a significant role in the recycling industry. Used catalytic converters are often valuable for their precious metal content. XRF enables recyclers to efficiently identify and extract valuable materials, thereby supporting the circular economy. Instead of mining new metals, which is resource-intensive and environmentally damaging, XRF allows for the extraction of platinum, palladium, and rhodium from old converters, helping to conserve resources and reduce the environmental impact of mining.

Conclusion

Catalytic converters are vital for reducing the harmful environmental impact of vehicle emissions. By employing XRF technology, we can ensure these devices remain effective in their mission to minimize pollution. From early detection of degradation to the recovery of valuable metals, XRF technology plays an indispensable role in making the automotive industry more environmentally responsible. As we move toward a cleaner, greener future, the integration of XRF in catalytic converter analysis will be a key element in achieving global sustainability goals.

Join Us

Subscribe to our email list for updates & promotions.