Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Top 5 Applications of Portable XRF Analysers in Industry and Research

Portable X-ray fluorescence (XRF) analyzers have revolutionized the way we analyze materials. These handheld devices offer rapid, non-destructive elemental analysis, making them indispensable in various industries and research fields. Here, we explore the top five applications of portable XRF analyzers, showcasing their versatility and impact.

1. Mining and Mineral Exploration

Rapid On-Site Analysis

Portable XRF analyzers are extensively used in the mining industry for on-site analysis of ores. They allow geologists and mining engineers to quickly determine the elemental composition of rocks and minerals. This immediate feedback helps in making informed decisions about where to drill, reducing both time and costs associated with sending samples to off-site laboratories.

Grade Control

In mining operations, grade control is crucial to ensure that the extracted ore meets the required quality standards. Portable XRF analyzers enable real-time monitoring of the mineral content, ensuring that only ore with the desired concentration of valuable elements is processed. This optimizes the efficiency of mining operations and enhances profitability.

2. Environmental Monitoring

Soil Contamination

Portable XRF analyzers are vital tools for assessing soil contamination. Environmental scientists use them to detect and quantify heavy metals and other pollutants in soil samples. This is particularly important for assessing the impact of industrial activities, waste disposal, and agricultural practices on soil health.

Hazardous Waste Management

These analyzers also play a crucial role in hazardous waste management. They help identify and quantify toxic elements in waste materials, ensuring proper handling, treatment, and disposal. This application is essential for protecting human health and the environment from the adverse effects of hazardous substances.

3. Archaeology and Cultural Heritage

Artifact Analysis

In archaeology, portable XRF analyzers are used to analyze artifacts and historical objects without causing damage. Researchers can determine the elemental composition of metals, ceramics, and other materials, providing insights into ancient manufacturing techniques, trade routes, and cultural interactions.

Site Surveys

Portable XRF devices are also employed in site surveys to analyze soil and sediment samples. This helps archaeologists identify areas with high concentrations of artifacts or historical significance, guiding excavation efforts and preserving valuable cultural heritage.

4. Manufacturing and Quality Control

Alloy Verification

In the manufacturing industry, especially in metallurgy, portable XRF analyzers are used to verify the composition of metal alloys. Ensuring that the materials meet specified standards is crucial for maintaining product quality and safety. These analyzers provide rapid, accurate results, facilitating efficient quality control processes.

Coating Thickness Measurement

Portable XRF analyzers can measure the thickness of coatings and platings on various substrates. This is particularly important in industries such as automotive, aerospace, and electronics, where precise coating thickness is critical for product performance and longevity.

5. Recycling and Scrap Metal Sorting

Material Identification

In the recycling industry, portable XRF analyzers are used to identify and sort different types of metals. This is essential for efficient recycling processes, ensuring that materials are correctly categorized and processed. Accurate identification of metals also enhances the quality of recycled products.

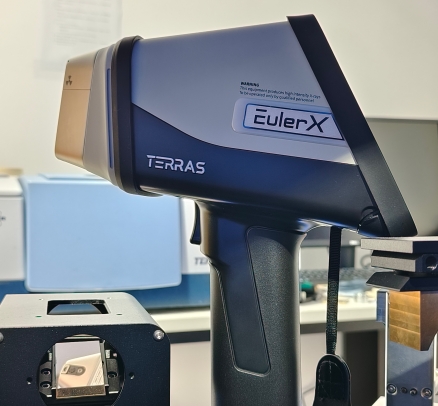

The EulerX 900 series has proved to be an excellent choice for metal analysis in a wide fields, providing fast, accurate results directly to the user. Thanks to its cutting-edge electronics and sophisticated mathematical algorithms, the EulerX 900 series ensures superior measurement quality within seconds. This makes it an ideal tool for inspecting and analyzing incoming materials, finished products, and in-process production parts in a non-destructive manner. Its simplicity of operation allows users to quickly view alloy grade and chemical composition on the touch screen display, achieving laboratory-quality analysis with minimal training and virtually no need for sample preparation, regardless of the sample is shape or size.

Precious Metal Recovery

Portable XRF analyzers are valuable tools for recovering precious metals from electronic waste and other scrap materials. They help identify components with high concentrations of valuable elements like gold, silver, and platinum, maximizing the economic return from recycling efforts.

Conclusion

The versatility and efficiency of portable XRF analyzers make them indispensable across a wide range of industries and research fields. From mining and environmental monitoring to archaeology and manufacturing, these devices provide rapid, accurate elemental analysis that drives informed decision-making and enhances operational efficiency. As technology continues to advance, the applications of portable XRF analyzers are likely to expand even further, solidifying their role as critical tools in modern industry and research.

Join Us

Subscribe to our email list for updates & promotions.