catalytic convertor

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Turning Trash into Treasure: Repurposing and Reselling Used Catalytic Converters

In today's world, sustainability and innovation go hand in hand. One of the most intriguing and profitable ways to embrace both is through the repurposing and reselling of used catalytic converters. Often overlooked, these automotive components are a treasure trove of valuable materials and potential income. This blog will delve into how you can transform what many consider junk into a lucrative venture while contributing positively to the environment.

Understanding Catalytic Converters

Catalytic converters are essential parts of a vehicle's exhaust system, designed to reduce harmful emissions. They contain precious metals like platinum, palladium, and rhodium, which act as catalysts in chemical reactions that convert toxic gases into less harmful substances. Over time, these converters wear out and need replacement, leading to a substantial amount of used catalytic converters available for repurposing and reselling.

The Value of Used Catalytic Converters

The precious metals inside catalytic converters are valuable commodities. Here’s a breakdown of why they’re so sought after:

Platinum: Used in various industrial applications, including electronics and medical devices.

Palladium: Widely used in electronics, dentistry, and as an investment commodity.

Rhodium: Highly valuable due to its rarity and use in catalytic applications and jewelry.

Extracting and recycling these metals from used catalytic converters is both economically beneficial and environmentally responsible. Instead of letting these components end up in landfills, they can be repurposed or resold, creating a profitable cycle.

The role of XRF analyzers in reusing and reselling old catalytic converters

XRF (X-ray fluorescence) analyzers play a key role in reusing and reselling old catalytic converters. It is a non-destructive analytical technique that determines the precious metal content of a material by measuring its elemental composition. Here’s how XRF analyzers play a role in this process:

Fast and accurate composition analysis: XRF analyzers can quickly and accurately determine the content of precious metals such as platinum, palladium and rhodium in catalytic converters. This rapid analysis capability is particularly important for evaluating and classifying large volumes of used catalytic converters.

Non-destructive testing: Because XRF analysis is non-destructive, it will not damage the catalytic converter or the precious metals within it. This means you can test without compromising the integrity of the part, thus maximizing its value.

Save time and cost: Traditional chemical analysis can take a lot of time and resources, but XRF analyzers can complete a test in a few minutes and do not require expensive reagents and processing equipment. This helps increase efficiency and reduce costs.

Support decision-making: By quickly obtaining the accurate content of precious metals in your catalytic converter, you can better develop recycling strategies and pricing strategies. This helps maximize profits and optimize resource utilization.

Quality Control: XRF analyzers can be used to perform quality control on used catalytic converters received from suppliers. By verifying its precious metal content, you can ensure you are receiving high-quality materials, making the reuse process more efficient and reliable.

With EulerX 900 Handheld XRF spectrometers, it takes just seconds to give the result comparing with hours or days as in a laboratory. Together with simple operation training and easy sample preparation, they are ideal and affordable solution for the daily business for quality control and price evaluation during catalyst’s dealing.

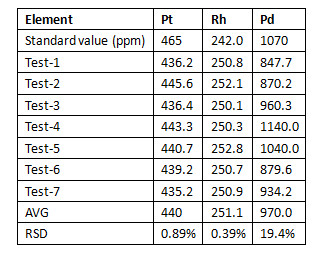

Following is the testing data for a catalyst standard to verify the testing stability of handheld XRF analyzer with a catalyst calibration.

To summarize, XRF analyzers play a vital role in the process of reusing and reselling old catalytic converters. It drives the process forward by not only providing fast, accurate composition analysis but also supporting decision-making, saving time and costs, and helping ensure material quality.

Join Us

Subscribe to our email list for updates & promotions.