Coating

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Revolutionizing Coating Thickness Measurement: The Role of Terra Scientific Handheld XRF Analyzer

In the dynamic world of industrial manufacturing, the meticulous control of coating thickness holds paramount importance. Coatings, whether metallic or non-metallic, serve a multitude of purposes ranging from corrosion protection to enhancing aesthetic appeal. The advent of advanced technologies has significantly transformed the landscape of coating thickness measurement, with handheld X-ray fluorescence (XRF) analyzers emerging as a game-changer in this domain. Among these, the Terra Scientific Handheld XRF Analyzer, particularly the EulerX 900 series, stands out for its reliability, portability, and efficiency. This article delves into the nuances of coating thickness measurement, the unique capabilities of handheld XRF analyzers, and the transformative impact of Terra Scientific's EulerX 900 series.

The Significance of Coating Thickness Measurement

Coatings, whether applied to metals, plastics, or other substrates, serve a myriad of purposes across diverse industries. From protecting against corrosion and wear to enhancing functionality and appearance, coatings play a pivotal role in ensuring the longevity and performance of manufactured goods. However, the effectiveness of coatings is directly correlated with their thickness. Coatings that are too thin may fail to provide adequate protection, while excessively thick coatings can lead to manufacturing defects and increased costs. Hence, precise control over coating thickness is essential to meet quality standards, regulatory requirements, and customer expectations.

Traditional Methods vs. Handheld XRF Analysis

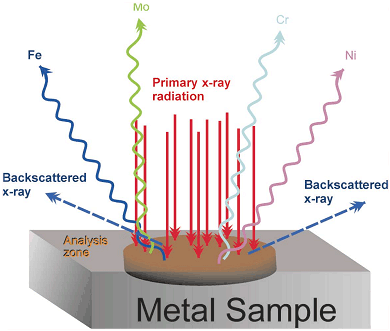

Historically, coating thickness measurement relied on labor-intensive and time-consuming techniques, such as magnetic or eddy current gauges. While effective for certain applications, these methods often lacked the versatility and precision demanded by modern manufacturing processes. In contrast, handheld XRF analyzers offer a non-destructive, rapid, and accurate means of assessing coating thickness. By utilizing X-ray fluorescence spectrometry, these devices can analyze the elemental composition of coatings and substrates, providing insights into thickness with exceptional accuracy. This versatility extends to a wide range of materials and coatings, making handheld XRF analysis indispensable in industries ranging from automotive to aerospace.

The Unique Capabilities of Handheld XRF Analyzers

Handheld XRF analyzers, such as the EulerX 900 series from Terra Scientific, boast a host of features that set them apart in the realm of coating thickness measurement. Firstly, their portability and ease of use enable operators to conduct on-site measurements without the need for cumbersome equipment or sample preparation. This not only saves time but also enhances productivity and workflow efficiency. Moreover, handheld XRF analyzers offer rapid results, with test outcomes available in seconds rather than hours or days. This real-time feedback facilitates timely decision-making and quality control, reducing the likelihood of defects and rework.

Furthermore, handheld XRF analyzers are non-destructive, meaning they do not alter or damage the materials being tested. This is particularly advantageous when dealing with delicate or valuable substrates, where preserving material integrity is paramount. Additionally, these devices are equipped with advanced software algorithms and user-friendly interfaces, allowing operators to interpret results quickly and accurately. Whether measuring single or multiple layers of coatings, handheld XRF analyzers offer unparalleled precision and reliability, making them indispensable tools in the modern manufacturing arsenal.

Applications Across Industries

The applications of handheld XRF analyzers for coating thickness measurement are diverse and far-reaching. In the automotive industry, for instance, these devices are used to ensure the uniformity and integrity of paint coatings, protecting vehicles from rust and corrosion. Similarly, in the aerospace sector, handheld XRF analyzers play a crucial role in verifying the thickness of protective coatings on aircraft components, safeguarding against fatigue and structural failure. Moreover, in the electronics industry, where miniaturization and precision are paramount, these devices are utilized to assess the thickness of conductive and insulating layers on circuit boards, ensuring optimal performance and reliability.

Terra Scientific's EulerX 900 Series: Leading the Way

Among the myriad handheld XRF analyzers available in the market, Terra Scientific's EulerX 900 series stands out for its exceptional performance, reliability, and versatility. Engineered with state-of-the-art technology and precision optics, the EulerX 900 series offers unmatched accuracy and repeatability in coating thickness measurement. Whether analyzing metallic coatings on steel substrates or non-metallic coatings on plastic components, these devices deliver consistent and reliable results across diverse materials and applications.

Moreover, the EulerX 900 series is designed for seamless integration into manufacturing processes, with intuitive software interfaces and customizable measurement protocols. This enables operators to tailor the analyzer's settings to specific coating types, substrates, and thickness ranges, ensuring optimal performance and efficiency. Furthermore, Terra Scientific's commitment to ongoing research and development ensures that the EulerX 900 series remains at the forefront of technological innovation, continuously evolving to meet the evolving needs of the industry.

Conclusion

In conclusion, the measurement of coating thickness is a critical aspect of modern manufacturing, with far-reaching implications for product quality, performance, and cost-effectiveness. Handheld XRF analyzers, exemplified by Terra Scientific's EulerX 900 series, have emerged as indispensable tools in this endeavor, offering unparalleled accuracy, speed, and versatility. By leveraging the principles of X-ray fluorescence spectrometry, these devices provide manufacturers with real-time insights into coating thickness, enabling informed decision-making and quality control. As the industry continues to evolve, handheld XRF analyzers will undoubtedly play a central role in driving innovation and excellence in coating thickness measurement.

Join Us

Subscribe to our email list for updates & promotions.