Metal & Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

DETERMINATION OF LEAD IN COPPER WATER PIPES

Copper water pipes have been a staple in plumbing systems for centuries, owing to copper's exceptional properties such as corrosion resistance, safety, malleability, ease of joining, reliability, and recyclability. Throughout history, copper has been instrumental in delivering safe drinking water to communities around the world.

The Importance of Testing Copper Water Pipes

Ensuring that copper water pipes and fittings are devoid of lead is paramount due to the severe health risks associated with lead exposure. Regulations have gradually phased out the use of lead in solder and flux since 1978, and there has been a continuous effort to reduce lead content in brass components used in plumbing systems. Modern standards dictate that new components must contain less than 0.25% lead concentration when in contact with water, with various countries instituting stringent criteria, such as the NSF 61 standard, to safeguard drinking water quality from copper alloy plumbing components.

Despite regulatory measures, there remains a risk of elevated lead concentrations in brass valves, fittings, and components within copper piping systems, often due to cost considerations by some manufacturers. To cut production costs, many manufacturers opt for lead brass rather than pure copper as the primary pipe material, thereby increasing the risk of lead contamination in water. Furthermore, in a bid to further reduce costs, some manufacturers may resort to using raw materials with high lead content to enhance processing performance or even recycle waste copper products for recasting, exacerbating the pollution risk. As health concerns mount and mandatory standards are implemented in related industries, there is an urgent need for quantitative analysis of elements, particularly those posing health risks. Consequently, rigorous selection of raw materials, stringent product production and processing, and robust quality and safety monitoring by relevant manufacturers and regulatory bodies have become imperative.

The Role of Terra Series Handheld XRF Analyzers

The utilization of Terra series handheld XRF analyzers facilitates accurate quantitative analysis of various metal and non-metal elements, significantly enhancing the precision of product compliance testing. These portable instruments offer ease of use and produce highly readable analysis results, enabling on-site analysis under diverse conditions.

Evaluating Lead Concentration in Copper Pipes

Given the multitude of copper alloys, quickly determining compliance with relevant standards during on-site analysis poses a challenge. The EulerX 900 series handheld copper alloy analyzer addresses this challenge by automatically matching copper alloy models according to element composition and content through its built-in alloy grade database, thereby streamlining compliance detection. Additionally, the EulerX 900 copper analyzer offers several distinct advantages:

Portability and ease of on-site use

-Non-destructive testing without the need for sample preparation

-Short detection time yielding reliable quantitative analysis results

The EulerX 900 series handheld copper alloy analyzers provide a comprehensive solution for quality monitoring and safety compliance testing of copper products used in water supply systems. Equipped with high-performance X-ray tubes and Si-Pin detectors, these analyzers offer fast and accurate element content analysis. Furthermore, an optional large-area silicon drift detector enhances instrument resolution and reduces analysis time.

Analyzing Lead in Copper Alloy with Handheld XRF Analyzer

During analysis, standard samples are employed to establish a working curve for quantitative analysis using the basic FP (Fundamental Parameter) method, thereby eliminating the need for additional standard sample calibration during actual quantitative analysis of elements.

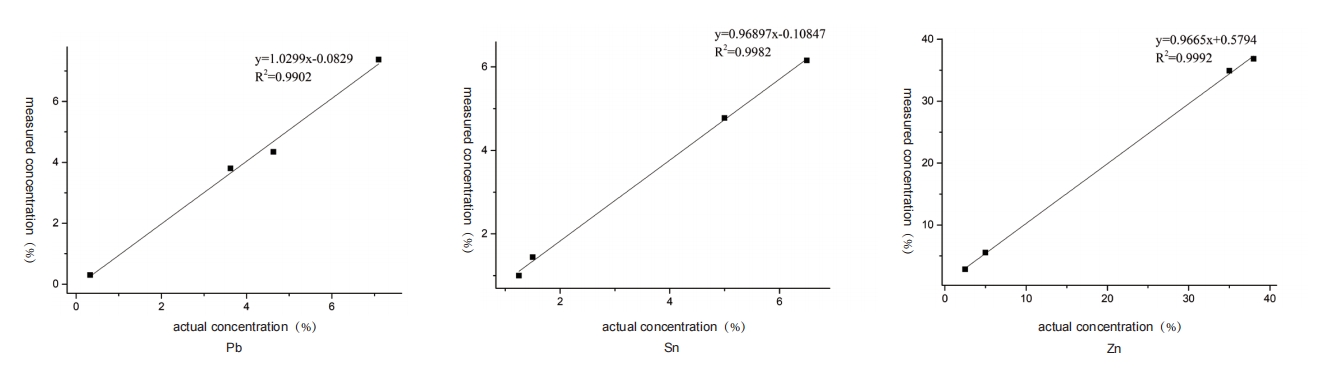

Initially, different copper alloy samples are analyzed with a test duration of 30 seconds, focusing on the contents of lead (Pb), zinc (Zn), and tin (Sn). The analysis utilizes actual content and measured values of elements for linear fitting, demonstrating the instrument's ability to accurately reflect the actual content of elements in various samples and its adeptness at on-site analysis.

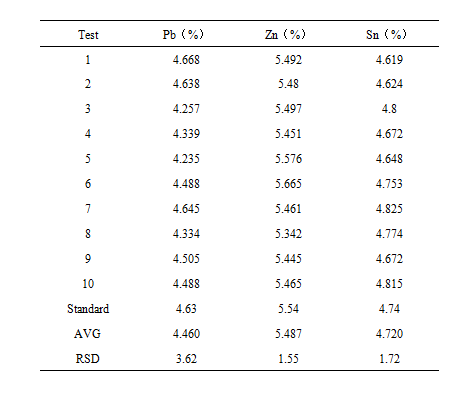

The experiment also assesses the instrument's measurement repeatability by conducting ten repeated tests on a sample with known content under identical conditions, each lasting 30 seconds. The tests reveal the instrument's good repeatability in analysis results, indicating stability, accuracy, and reliability.

Conclusion

Terra EulerX 900 series handheld XRF analyzers play a pivotal role in accurately analyzing lead concentration and other heavy metal elements in tested alloy samples, thereby enhancing the reliability and credibility of on-site analysis and product inspection. These analyzers serve for rapid product screening by quality inspection departments or in the selection of raw materials in alloy processing. Their introduction enhances efficiency in quality testing, environmental risk assessment, and alloy product processing, ultimately reducing time and costs incurred.

Join Us

Subscribe to our email list for updates & promotions.