Metal & Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Comprehensive Insights into Ferroalloys: Enhancing Steel Production Dynamics

Comprehensive Insights into Ferroalloys: Enhancing Steel Production Dynamics

Ferroalloys stand as indispensable components within the intricate web of steel production, comprising diverse alloys of iron intricately laced with elements such as manganese (Mn), aluminum (Al), or silicon (Si). These alloys wield significant influence, imbuing steel with distinctive properties and performing critical functions throughout its production cycle. This article embarks on a thorough exploration of the multifaceted roles of ferroalloys, delves into the pivotal significance of the X-ray Fluorescence (XRF) technique for their precise analysis, and introduces the EulerX 900 Handheld XRF Analyzer as a revolutionary tool poised to redefine ferroalloy analysis.

The Essential Functions of Ferroalloys

At the heart of steel production, ferroalloys play a multifarious role, underpinning various stages of the process. From augmenting steel's mechanical properties to facilitating essential reactions, ferroalloys serve as catalysts for optimization and refinement. Notably, ferrosilicon alloy, manganese-silicon alloy, and ferromanganese alloy emerge as frontrunners in this domain, renowned for their prowess in deoxidation and alloy enhancement.

Deoxidation, a critical step in steelmaking, necessitates the removal of oxygen to prevent structural defects and enhance steel's mechanical integrity. Ferroalloys, acting as deoxidizers, deftly eliminate excess oxygen, ensuring the attainment of the desired solidification structure and mitigating the risk of imperfections. Furthermore, ferroalloys double as desulfurizers and dephosphorizers, curbing the detrimental effects of sulfur and phosphorus, thereby refining steel's purity and performance.

Among these roles, ferrosilicon stands out as a cornerstone deoxidizer, lauded for its effectiveness and cost efficiency. Its widespread adoption underscores the indispensable nature of ferroalloys in optimizing steel quality and bolstering production efficiency.

Unlocking Precision with X-ray Fluorescence (XRF) Technique

Accurate characterization of ferroalloy composition forms the bedrock of quality control in steel production. While conventional methods like "wet chemistry" have long prevailed, their labor-intensive nature and protracted sample preparation times have spurred the exploration of alternative approaches. Enter XRF spectrometry, heralded for its rapidity, versatility, and simplicity in ferroalloy analysis, particularly in the case of FeSi alloys.

XRF analysis heralds a new era of efficiency, boasting swift analysis times, expansive detection ranges, and unwavering reliability. Sample preparation methodologies vary according to desired precision levels, with options ranging from powder cups to fused beads, each tailored to ensure optimal results across diverse ferroalloy compositions. These techniques, underpinned by standardized protocols and meticulous calibration, empower steelmakers with unprecedented insight into their ferroalloy compositions, thereby fortifying their quality control endeavors.

Introducing the EulerX 900 Handheld XRF Analyzer: A Paradigm Shift in Ferroalloy Analysis

The EulerX 900 series handheld alloy analyzer epitomizes a quantum leap in ferroalloy analysis, harnessing state-of-the-art Energy Dispersive X-ray Fluorescence technology (ED-XRF) to deliver unparalleled sensitivity and detection limits. This portable powerhouse transcends traditional boundaries, offering seamless elemental analysis of ferroalloys with unprecedented speed and accuracy.

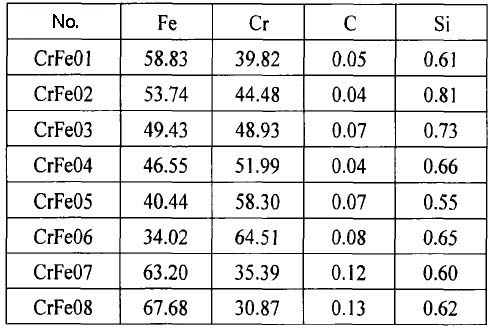

Elements concentration of ferrochromium

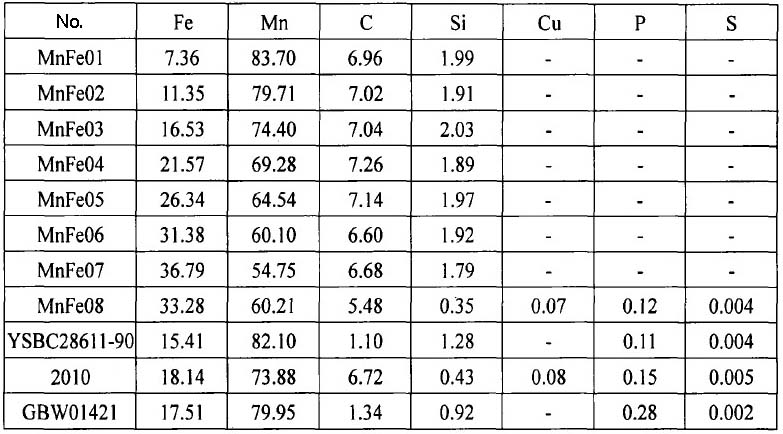

Elements concentration of ferromanganese

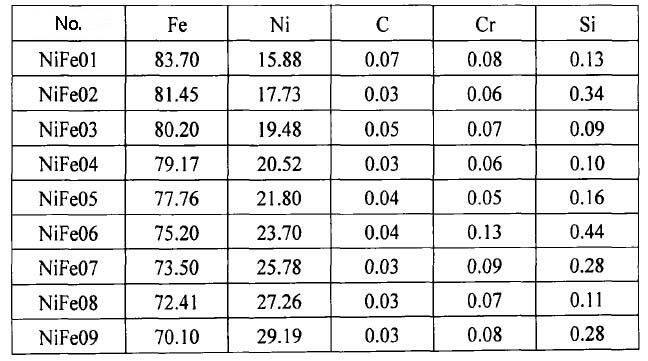

Elements concentration of ferronickel

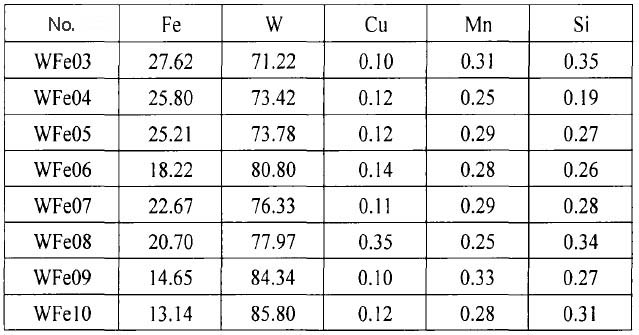

Elements concentration of ferrotungsten

Embodying the pinnacle of technological innovation, the EulerX 900 series revolutionizes on-site ferroalloy analysis, obviating the need for cumbersome sample preparation while ensuring rapid detection and precise quantitative analysis. Its ergonomic design and intuitive interface render it a versatile tool for steel plants, empowering operators to conduct real-time analyses with unparalleled ease and efficiency.

In addition to its analytical prowess, the EulerX 900 series is fortified with a suite of advanced features, including a high-performance X-ray tube and cutting-edge detectors, ensuring unrivaled resolution and analysis speed. Optional enhancements, such as the large-area silicon drift detector, further elevate its capabilities, cementing its status as an indispensable asset in the modern steelmaking arsenal.

Conclusion: Pioneering a New Frontier in Steel Production

As the steel industry charts a course towards greater efficiency and sustainability, the pivotal role of ferroalloys looms larger than ever before. From optimizing steel quality to streamlining production processes, these alloys serve as linchpins in the pursuit of excellence. The advent of advanced analytical techniques like XRF spectrometry, coupled with groundbreaking innovations such as the EulerX 900 handheld analyzer, heralds a new era of possibility, empowering steelmakers with unparalleled insights and capabilities.

As steel production evolves, embracing these technologies promises to unlock new frontiers of efficiency, quality, and sustainability, ensuring a prosperous future for the global steel industry. With ferroalloys at the helm of this transformation, the journey towards a brighter tomorrow is poised to unfold with unwavering resolve and boundless potential.

Join Us

Subscribe to our email list for updates & promotions.