Metal & Alloy

A high-tech enterprise focusing on the development and application of X-ray technology products, committed to becoming a leading supplier of X-ray industrial testing solutions.

Metal Dentures Material Testing: Ensuring Quality and Reliability

In the realm of dental prosthetics, dentures play a vital role in restoring oral function and aesthetics for individuals with missing teeth. These dental appliances come in various forms, materials, and designs, each tailored to meet the diverse needs and preferences of patients. Among the different types of dentures available, those crafted from metal materials occupy a significant position, offering unique advantages and challenges that warrant careful consideration and evaluation.

Understanding Metal Dentures

Metal dentures, also known as metal-based dentures, are prosthetic appliances constructed primarily from metal alloys. These alloys typically comprise a combination of metals such as cobalt, chromium, and occasionally gold, among others. Unlike their counterparts made from ceramics or resins, metal dentures possess distinct characteristics that make them a preferred choice for certain individuals.

One common type of metal denture is the cobalt-chromium alloy denture, which consists of a base and teeth crafted from a blend of cobalt and chromium metals. The base of the denture is designed to fit snugly against the gum line, providing stability and support, while the teeth are fashioned to resemble natural enamel in both appearance and function. Another variant is the gold denture, which, as the name suggests, incorporates gold as a primary component alongside other metal alloys. Gold dentures are renowned for their durability, biocompatibility, and aesthetic appeal, making them a sought-after option for those seeking a combination of functionality and luxury.

Benefits of Metal Dentures

Durability: Metal alloys used in dentures are inherently strong and resilient, capable of withstanding the rigors of daily use without succumbing to wear or damage. This durability ensures that metal dentures maintain their shape, function, and appearance over an extended period, providing long-term value and reliability to the wearer.

Biocompatibility: Metal alloys used in dentures are generally well-tolerated by the body, minimizing the risk of allergic reactions or adverse effects commonly associated with other materials. This biocompatibility ensures that metal dentures are safe and comfortable to wear, even for individuals with sensitive oral tissues or underlying health conditions.

Challenges in Metal Denture Material Quality

While metal dentures offer numerous benefits, ensuring the quality and authenticity of the materials used in their fabrication remains a critical concern. The high cost associated with precious metal alloys makes them susceptible to adulteration or substitution with inferior materials, such as low-grade metals or metal scraps. Consequently, manufacturers and dental laboratories must implement stringent quality control measures to prevent the proliferation of counterfeit or substandard products in the market.

One of the primary challenges in metal denture material quality is the risk of contamination or impurities introduced during the manufacturing process. The presence of foreign substances or alloying elements can compromise the structural integrity and biocompatibility of the dentures, leading to adverse reactions or premature failure in some cases. Additionally, variations in alloy composition or metallurgical properties may affect the mechanical strength, corrosion resistance, and aesthetic characteristics of the dentures, necessitating thorough testing and analysis to ensure compliance with regulatory standards and industry specifications.

Testing Methods for Metal Denture Materials

To address the complexities of metal denture material quality assessment, various testing methods and techniques have been developed to evaluate the chemical composition, mechanical properties, and performance characteristics of these dental prosthetics. These methods aim to identify any deviations or discrepancies from established standards and specifications, thereby ensuring the safety, efficacy, and reliability of metal dentures for patient use.

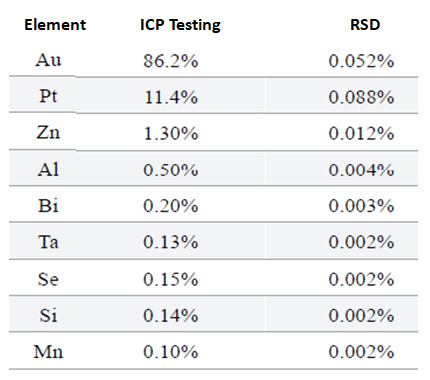

Chemical Analysis: Chemical analysis techniques, such as wet chemical analysis, titration, and inductively coupled plasma (ICP) spectroscopy, are commonly employed to determine the elemental composition of metal alloys used in dentures. These methods involve the dissolution of the sample material in a suitable solvent followed by the quantification of individual elements through spectroscopic or chromatographic analysis. While these techniques offer high sensitivity and accuracy, they are often time-consuming, labor-intensive, and require specialized equipment and expertise to perform.

Mechanical Testing: Mechanical testing methods, such as hardness testing, tensile testing, and fatigue testing, are employed to evaluate the mechanical strength, toughness, and durability of metal denture materials under simulated loading conditions. These tests involve the application of controlled forces or stresses to the sample material, followed by the measurement of relevant mechanical properties such as hardness, yield strength, and fracture toughness. By subjecting metal dentures to rigorous mechanical testing, researchers can assess their structural integrity, resistance to deformation, and ability to withstand occlusal forces during mastication and chewing.

Corrosion Testing: Corrosion testing techniques, including electrochemical impedance spectroscopy (EIS), potentiodynamic polarization, and salt spray testing, are used to assess the corrosion resistance and biocompatibility of metal denture materials in simulated oral environments. These methods involve exposing the samples to corrosive media or electrolytes under controlled conditions and monitoring the changes in corrosion potential, corrosion rate, and surface morphology over time. By evaluating the corrosion behavior of metal dentures, researchers can identify any susceptibility to localized or galvanic corrosion, pitting, or tarnishing that may compromise their long-term performance and biocompatibility.

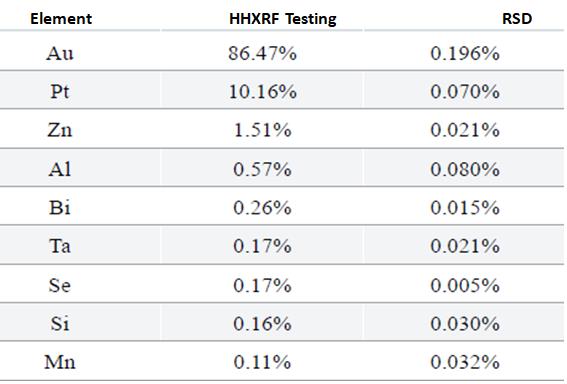

Following is a testing results comparison for testing the same sample with a HHXRF and ICP method.

1-Use Handheld XFR to test Gold Denture

2-Use handheld ICP-MS to test the same gold denture

Recent Advances in Metal Denture Material Testing:

In recent years, significant advancements have been made in the field of metal denture material testing, driven by innovations in analytical instrumentation, computational modeling, and materials science. These developments have enabled researchers and manufacturers to overcome many of the challenges associated with conventional testing methods and techniques, leading to more accurate, efficient, and cost-effective approaches for evaluating the quality and performance of metal dentures.

One notable advancement is the advent of handheld X-ray fluorescence (XRF) analyzers, which offer a non-destructive, rapid, and highly accurate method for analyzing the elemental composition of solid materials, including metal dentures. These portable devices utilize X-ray radiation to excite the atoms within the sample material, causing them to emit characteristic X-ray fluorescence that can be detected and quantified using specialized detectors. By measuring the intensity and energy of the emitted X-rays, handheld XRF analyzers can identify the presence and concentration of specific elements within the sample, providing valuable insights into its composition and purity.

Handheld XRF analyzers offer several advantages over traditional testing methods, including

Non-Destructive Analysis: Handheld XRF analyzers enable non-destructive analysis of metal denture materials, allowing for rapid, on-site testing without the need for sample preparation or alteration. This non-destructive approach preserves the integrity and usability of the dentures, minimizing downtime and logistical challenges associated with sample handling and transportation.

Real-Time Results: Handheld XRF analyzers provide instantaneous results, allowing for immediate decision-making and quality assurance. This real-time feedback enables manufacturers, dental laboratories, and regulatory authorities to quickly assess the quality and authenticity of metal denture materials, facilitating timely interventions and corrective actions as needed.

High Sensitivity and Accuracy: Handheld XRF analyzers offer high sensitivity and accuracy, capable of detecting trace elements and impurities at concentrations as low as parts per million (ppm). This high level of sensitivity ensures that even minor variations in alloy composition or metallurgical properties can be detected and quantified, providing comprehensive insights into the quality and performance of metal dentures.

Conclusion

In conclusion, metal dentures represent a versatile and durable option for individuals seeking to restore their oral health and aesthetics. However, ensuring the quality, safety, and performance of metal denture materials requires rigorous testing and analysis to identify any deviations or discrepancies from established standards and specifications. Advances in analytical instrumentation, computational modeling, and materials science have facilitated the development of novel testing methods and techniques, such as handheld XRF analysis, that offer non-destructive, rapid, and highly accurate means of evaluating the elemental composition and properties of metal dentures.

Join Us

Subscribe to our email list for updates & promotions.